It’s time

to change the way

we do business.

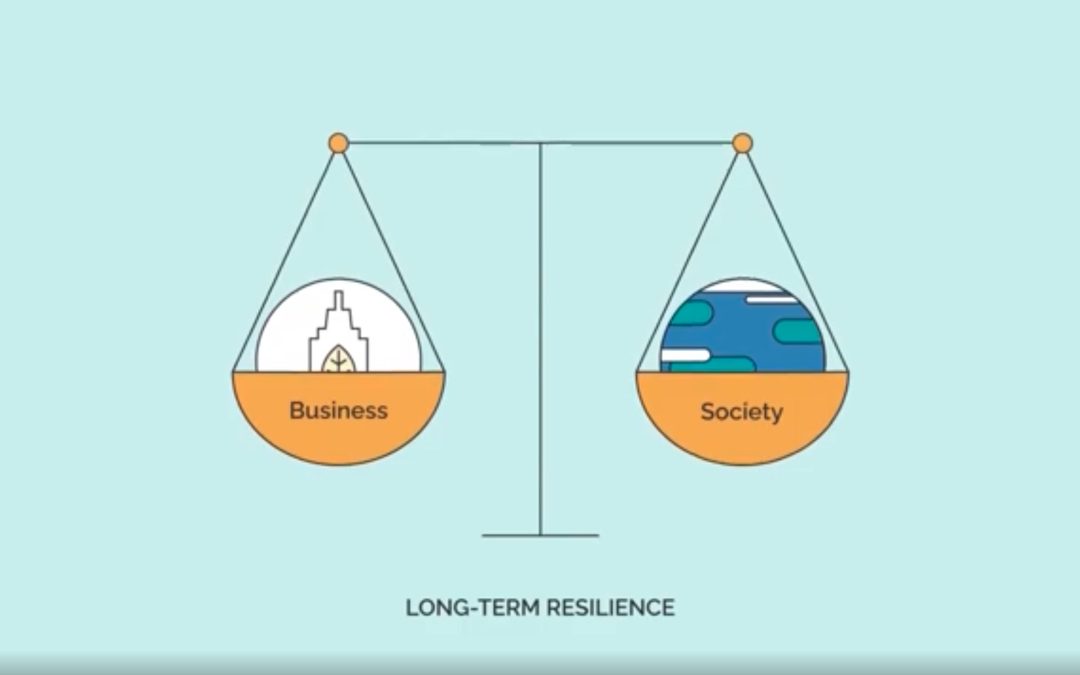

We believe that solving the world’s toughest problems is not only a moral imperative: it’s also an unprecedented business opportunity.

It’s what is called Creating Shared Value.

Building a sustainable and

equitable future.

We rally partners in business and society who combine their expertise to profitably solve pressing issues and create shared value.

Our purpose: build a more sustainable and inclusive future for all in Hong Kong SAR and Mainland China.

SVIHK is part of a global network launched in the United States in 2012 and now present on each continent.

Building regenerative, inclusive and equitable business models requires a collaborative ecosystem between all stakeholders.

We bridge business, government and non-profit to experience the power of collective impact.

Your accelerator

for change

Take our free Purpose assessment. In 5 minutes, check out what you are doing right and what the gaps are. We will support each step of your journey, from inspiring your people to finding partners, and help you measure your progress.

Our shared value

ambassadors

We’ve worked with organisations committed to achieving both economic growth and societal impact.

Latest Events, Blog

Resources

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

What is shared value?

Understand the concept of shared value coined at Harvard Business School and how companies align profit and purpose in a 4-minute-long video.

CUHK Business Lecture series – Shared value beyond responsible business

A thought-provoking seminar at CUHK Business School empowered over 200 students, showcasing the immense potential of CSV to drive economic growth and social impact, with the contribution of Denise Wong, Barclays Managing Director & co-Head of Sustainable Banking Group.

Jill Kong, Beetales, shares the buzzworthy story of a nature conservation company

Jill Kong, the co-founder of Beetales, pitched at the Impact Auction 2023. Check out this interview to know why this was a turning point.

Rethinking Shared Value: Reflections from ReThink HK 2023

Check out the key takeaways and insights from Veronica Sze, Nestlé Hong Kong, Olivia Wong, MTR Corporation, and Samuel Kwong, Chinachem.